It takes two days to train a cow to milk itself. This may sound like a farmer’s utopia, but at Bakerview EcoDairy, a robotic milker is just one of many dairy farm innovations being put to use.

Bill Vanderkooi, president and CEO of the Bakerview EcoDairy farm, seeks out all of the latest technologies to help him run his operation, which hosts an onsite market and agricultural education center. Armed with a master’s degree in animal science, Vanderkooi opened the 80-acre farm near Abbotsford, British Columbia, in June of 2010. He has since established himself as a pioneer among small-scale, sustainable farm owners.

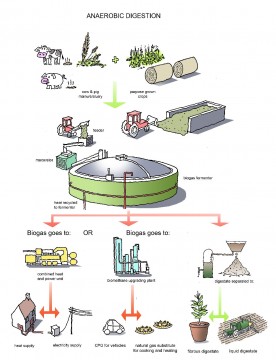

An anaerobic digester is one of the key technologies that Vanderkooi uses in his quest to reduce his farm’s ecological footprint. This machine turns the methane gas released from cow manure into electricity. About 65 percent of cow manure is composed of methane, making it an abundant energy resource. Over the course of a year, Bakerview EcoDairy is able to offset a third of the energy needed to operate the farm, thanks to the digester and a small herd of 50 cows.

So, how does anaerobic digestion work?

Before entering the digester, manure is heated to 100 degrees Fahrenheit, the perfect temperature to prime the appetite of picky microorganisms. Pistons push the hot manure into the main chamber where the microorganisms feast.